Our Introduction

Boilertech Systems Pvt. Ltd.

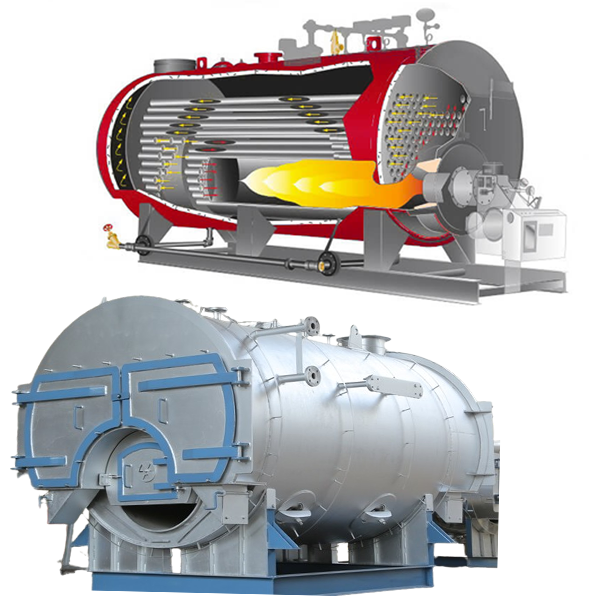

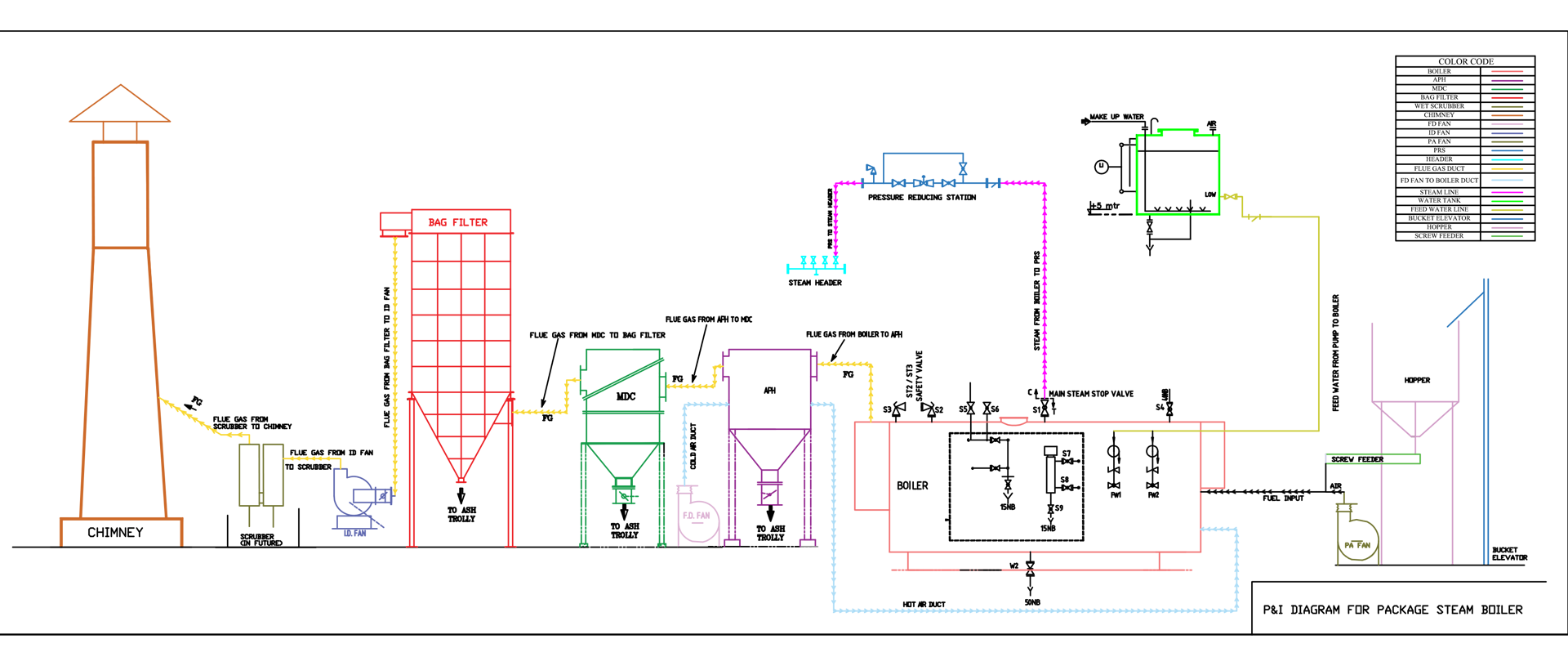

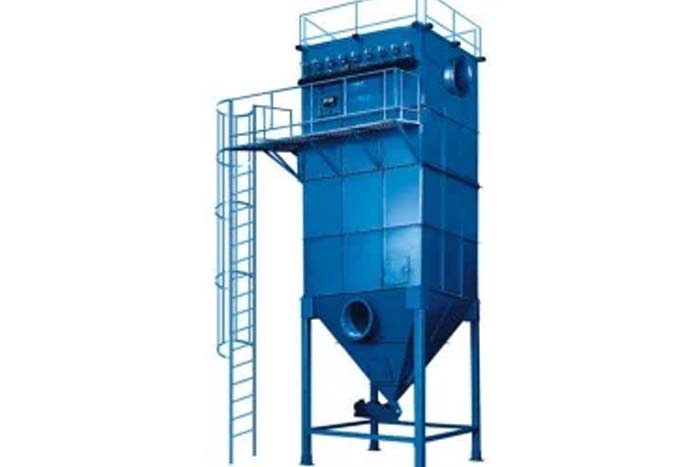

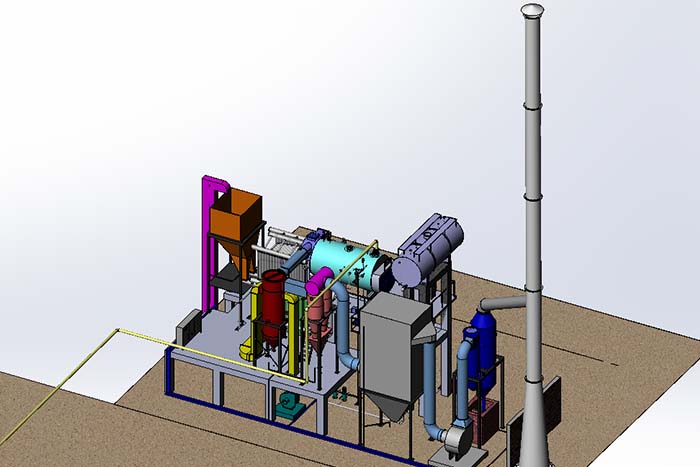

Boilertech Systems Pvt. Ltd. is a company specializing in providing solutions related to industrial boilers and steam systems. We manufacture Steam Boilers utilized in process heating/power generation, and provide turnkey solutions for various industries. The products are offered for the entire range of pressure and temperature for capacities ranging from 300 kilograms per hour to 25 tons per hour (TPH). The solutions offered for steam-generation are configured using a combustion system and integrating it with a steam generating system.

The Company has provided solutions for power plants and energy facilities as well as served industries like textiles, chemicals, and food processing that rely on steam for production processes.

Our expertise extends to designing and implementing steam distribution systems, which encompass steam headers, piping, and associated components. Boilertech Systems also provides critical maintenance services, ensuring that boiler systems and steam infrastructure operate seamlessly. Our consulting services help optimize boiler efficiency and ensure compliance with industry regulations. Serving diverse industries like power generation, manufacturing, and HVAC, Boilertech Systems is dedicated to enhancing energy efficiency and operational performance through tailored, high-quality solutions.